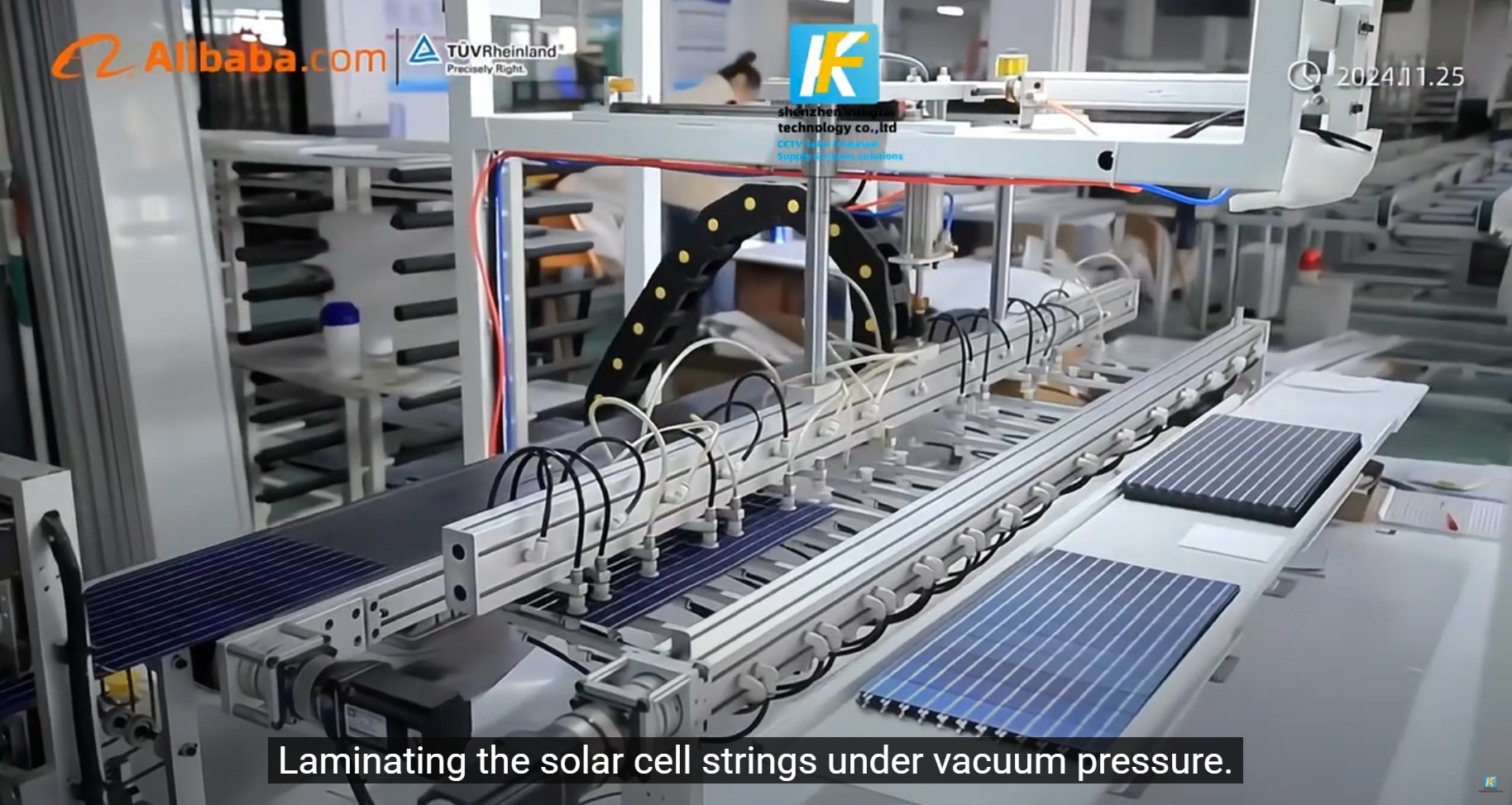

In lamination, we encapsulate strings under vacuum pressure with controlled temperature ramps, gel content, and cure times to achieve strong adhesion and moisture resistance. EVA/POE selection is matched to the deployment climate, while glass, backsheet, and frame options are specified for IP66-ready enclosures used in solar-powered CCTV systems, wind-solar hybrid kits, and custom off-grid energy boxes. Post-lamination, modules undergo edge-seal inspection, Hi-Pot/insulation tests, and EL re-checks to confirm there are no latent defects before integration with MPPT controllers and LiFePO4 batteries.

For integrators and distributors seeking a China solar kit manufacturer that can meet EU EMC/LVD/RoHS documentation and real-world durability, our lamination discipline is what keeps systems running in deserts, coastal zones, high-altitude forests, and flood-prone riverbanks. The result is a plug-and-play, scalable kit with predictable life-cycle costs—ideal for telecom towers, agricultural irrigation, pipeline corridors, and smart highway surveillance.